18 in. High StormChamber® Systems

Applications

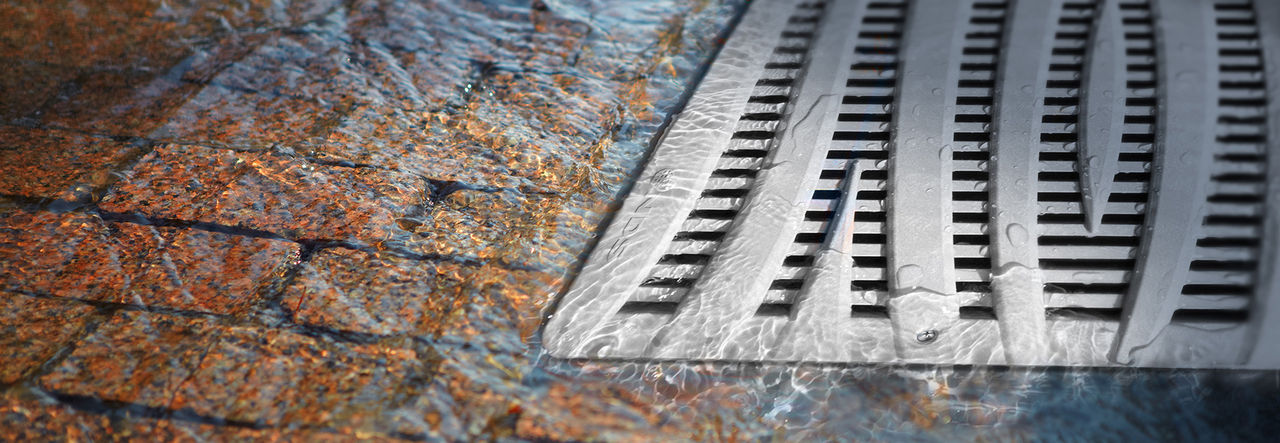

- Detains, infiltrates, and conveys stormwater runoff; modular system maximizes storage volume with a smaller footprint than traditional concrete and stone systems; easy to maintain

- Works in commercial, industrial, municipal, and residential settings to manage stormwater runoff; ideal for installing underneath parking lots, playing fields, and landscapes

- As part of a complete stormwater management system, the StormChamber® system works with a capture device or drainage inlet to detain, infiltrate, and convey collected stormwater

Installation

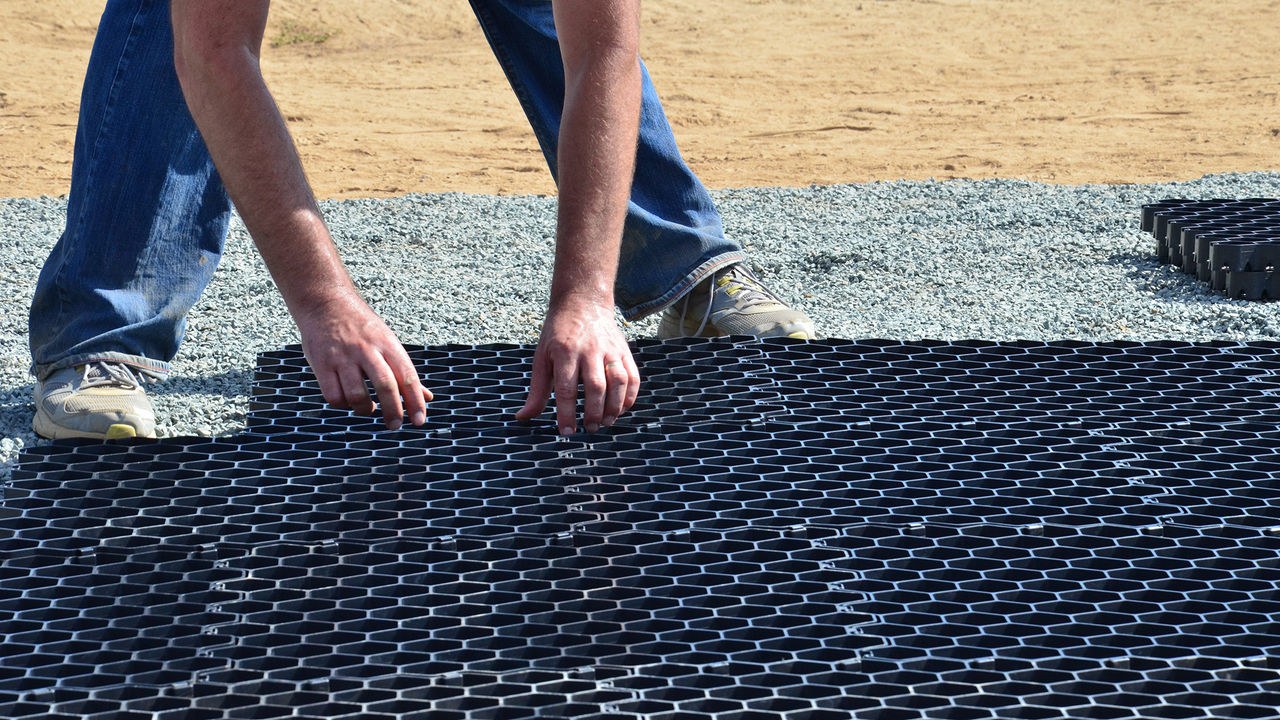

- Excavate trench

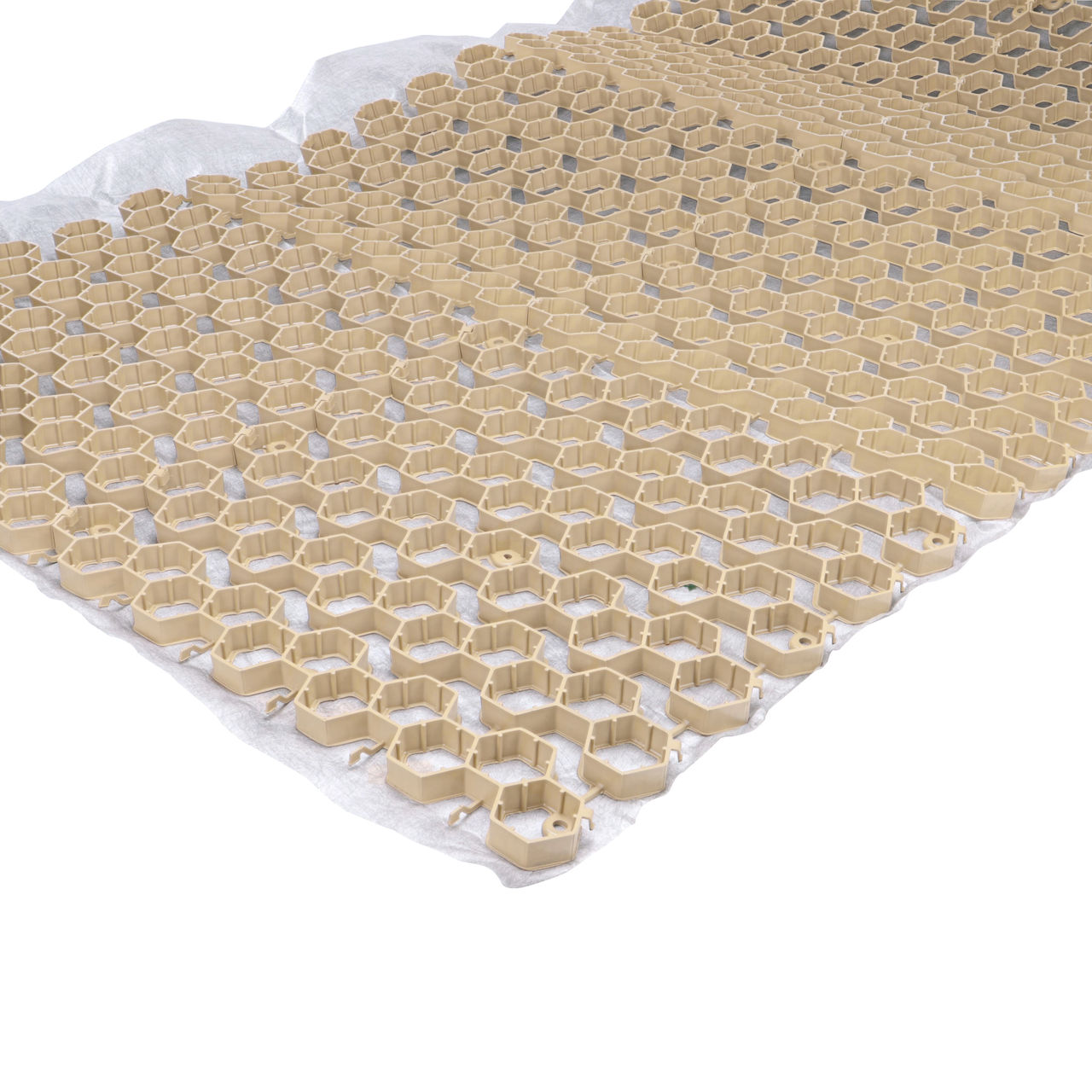

- Line walls with non-woven filter fabric

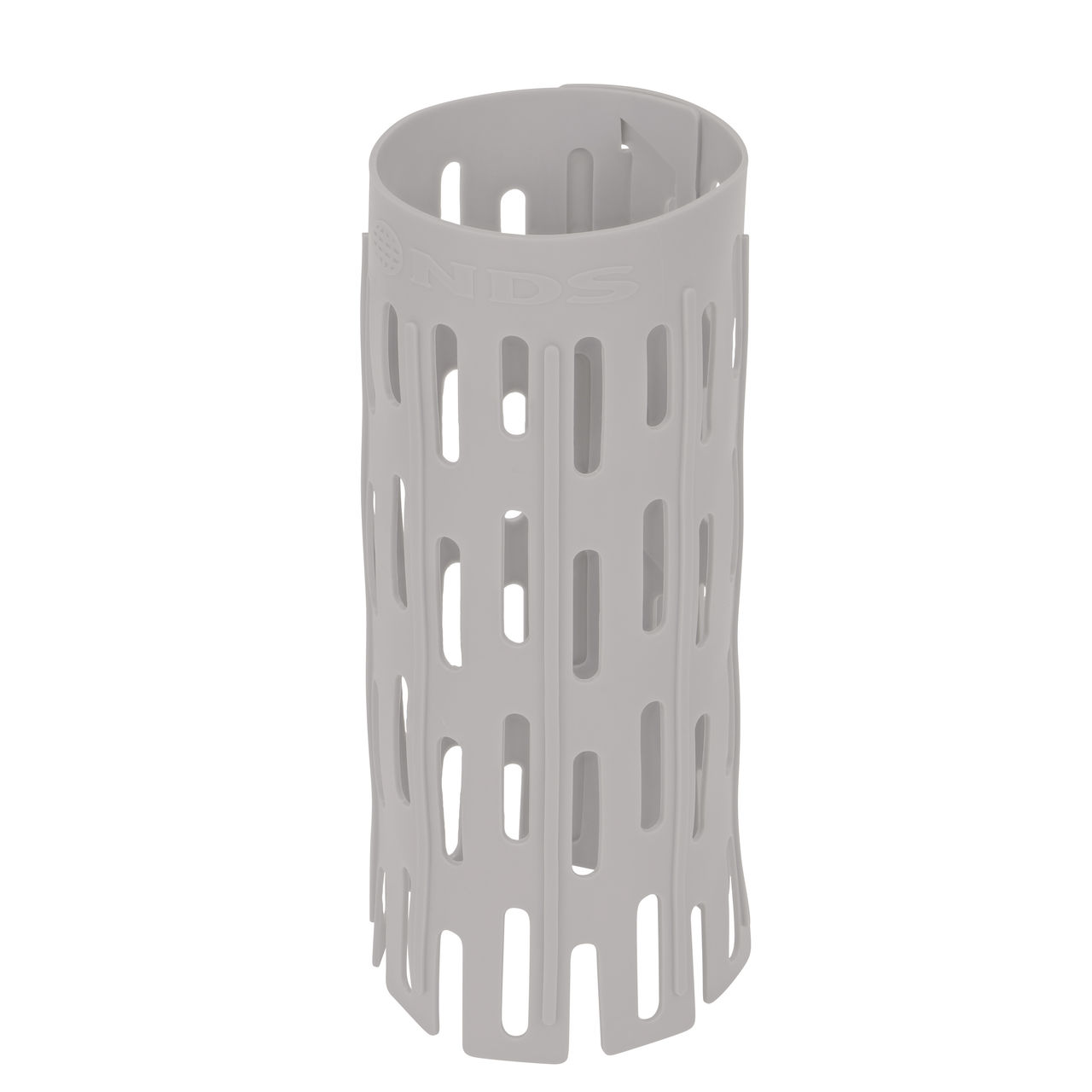

- Add SedimenTrap™ devices

- Add hard stone & woven stabilization fabric

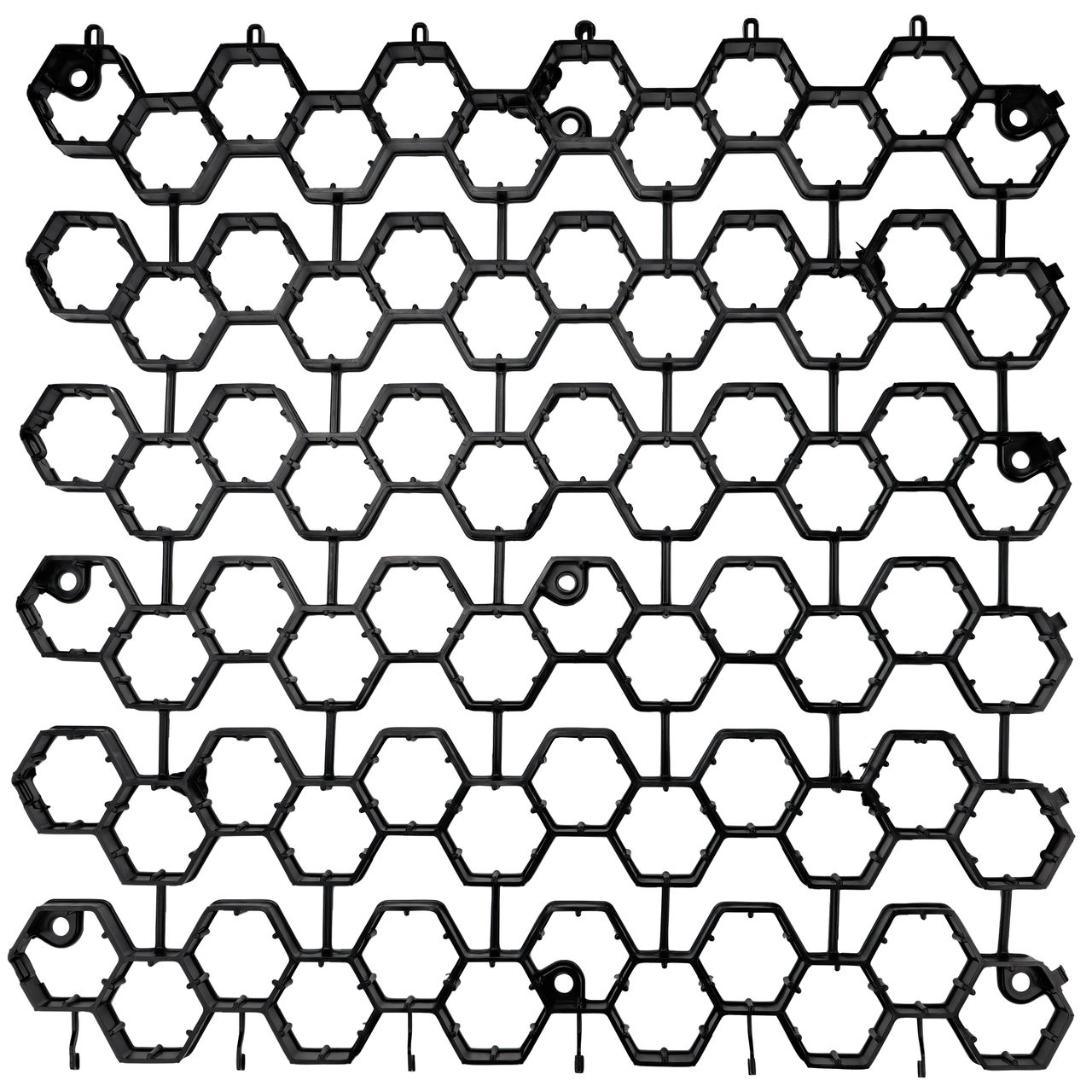

- Place overlapping chambers into trench & screw together

- Cut portal holes for pipe (read installation manual for details)

Maintenance Tips

- Use riser pipe connected to SedimenTrap™ device as an observation well and inspect with flashlight and stick

- Air vacuum when deposits approach within 6 in. of the invert height of connecting pipes between StormChamber® rows

- Determine maintenance schedule with quarterly inspections and logbook

- Maintenance without SedimenTrap device is done with water jet method

Materials & Sustainability

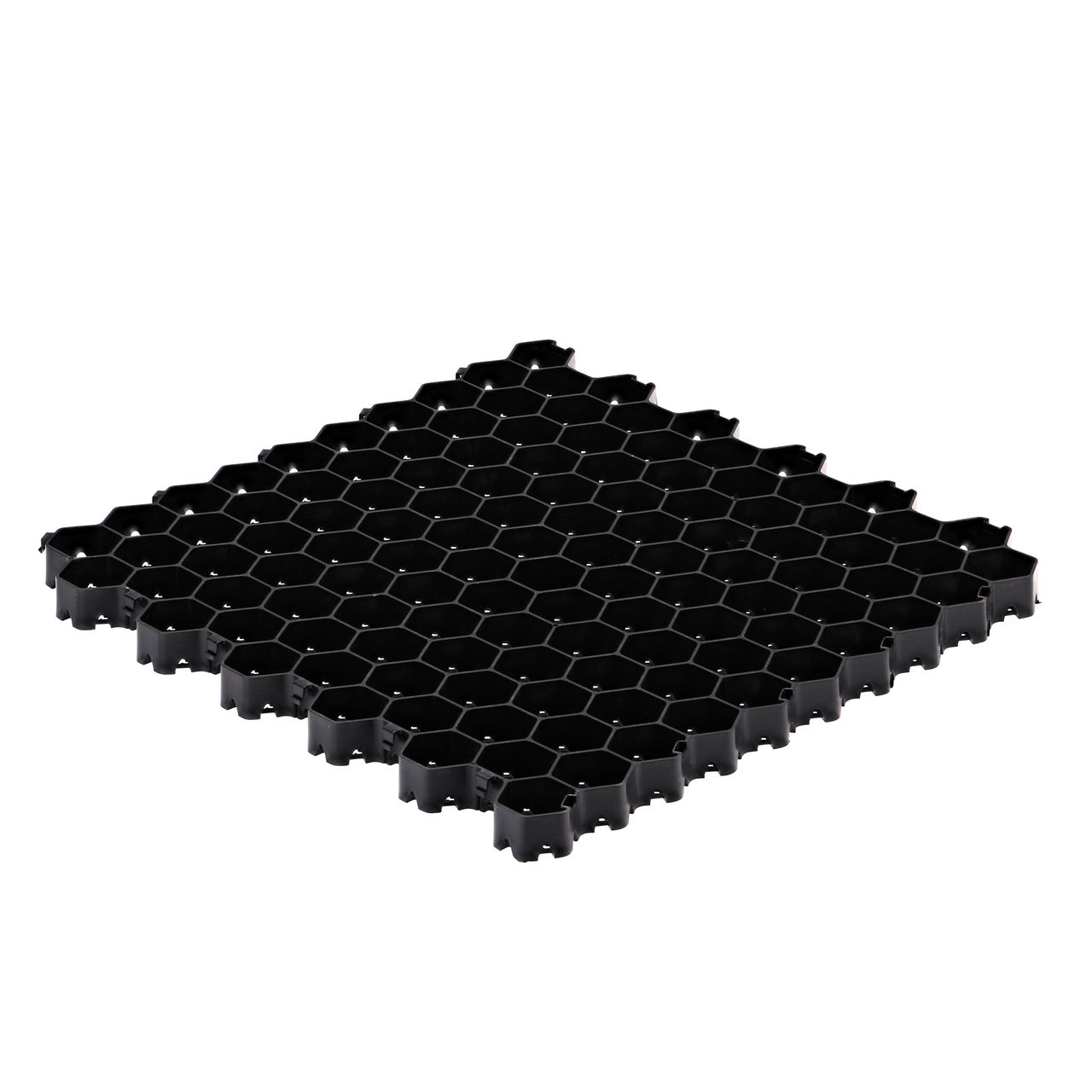

- StormChamber® unit is made of thermoformed high-density weight polyethylene (HMWPE)

- StormChamber® systems are made in the USA

Product Models

| Part Number | Description |

|---|---|

| SC-ST | SedimenTrap™ Sediment Capture Device for StormChamber® Systems, Black |

| SC-NWFF-500 | Non-woven Filter Fabric, 500 sq. ft., Black |

| SC-WFF-75 | Woven Stabilization Fabric, 562.25 sq. ft., Black |

| SC-FL-10 | 10 in. Frame and Lid for StormChamber® Systems |

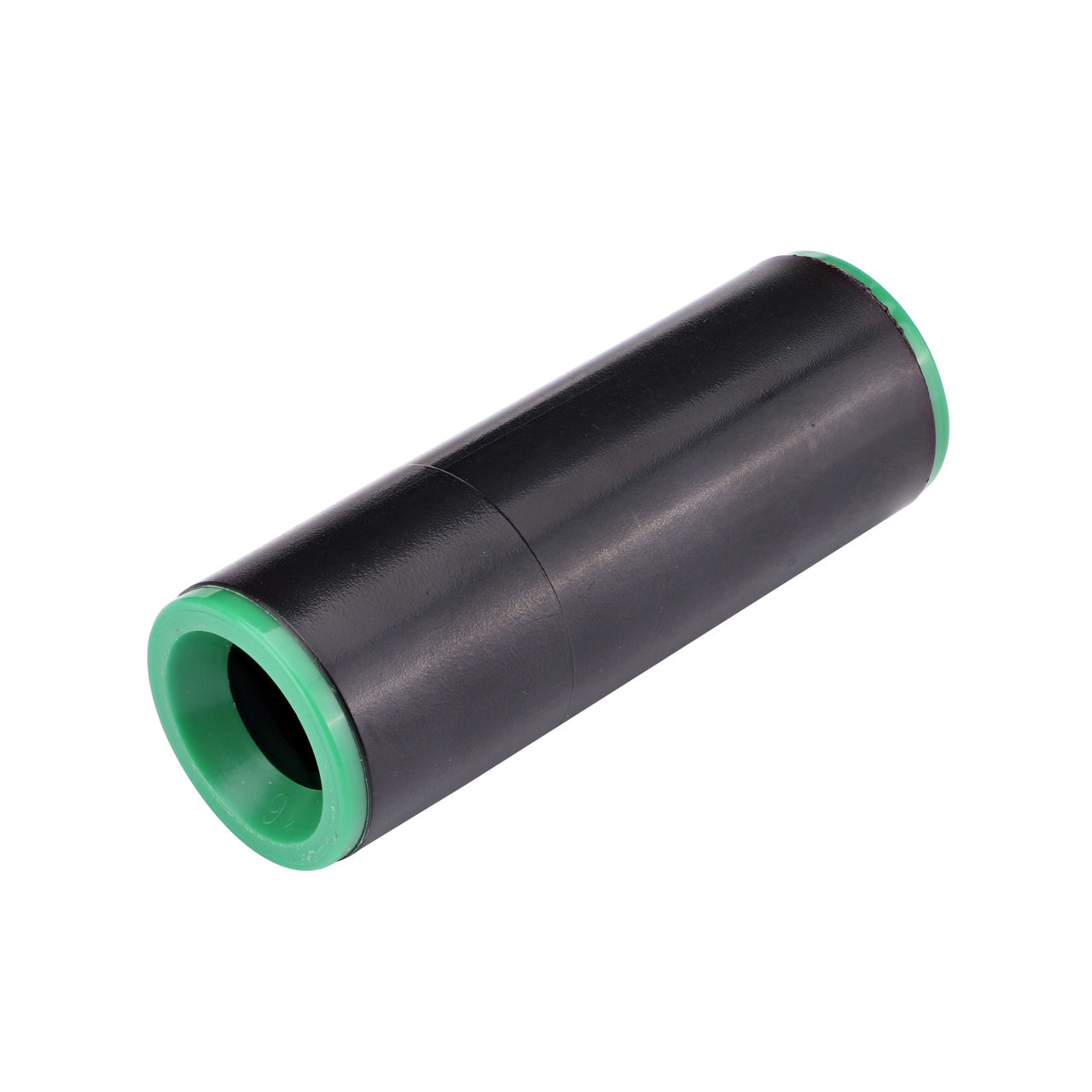

| SC-3020P | HDPE Corrugated Pipe, 30 in. X 20 in., Black |

| SC-2412P | HDPE Corrugated Pipe, 24 in. X 12 in., Black |

Literature & Resources

NDS StormChamber® Systems Chamber Installation Instructions

NDS StormChamber® Systems Chamber Bearing Capacity Guide

NDS StormChamber® Systems Design Calculator

Commercial Stormwater Product Solutions Brochure

Frequently Asked Questions

The NDS DesignWorx Team is available at every step of the design process. Let us take out the guesswork and show you how NDS products can help meet your project's specifications, reduce costs, or save time. Visit https://www.ndspro.com/submityourdesign

Unlike a manifold pipe system, sediment will be deposited only in row(s) that receive inflow, and mainly in the StormChamber SedimenTraps. Inflow row(s) will have a SedimenTrap in the first and last chamber of the row into which sediment accumulation can be monitored and vacuumed out through the 10 in. riser pipe directly above each SedimenTrap.

After opening the inspection/maintenance manhole cover, use a high-power flashlight or measuring stick to inspect the SedimenTraps. If the sediment is overflowing out of the SedimenTrap and into the chamber, it is ready for maintenance.

Unlike other competing systems, NDS StormChamber systems do not require a camera to inspect the entire length of the sediment row for buildup. We also do not require that the row be flushed, so no water jetting is required. The StormChamber system only takes minutes to inspect/maintain by simply opening a manhole cover and checking for buildup. Once it is determined that maintenance is required, only a simple vacuum truck is required.

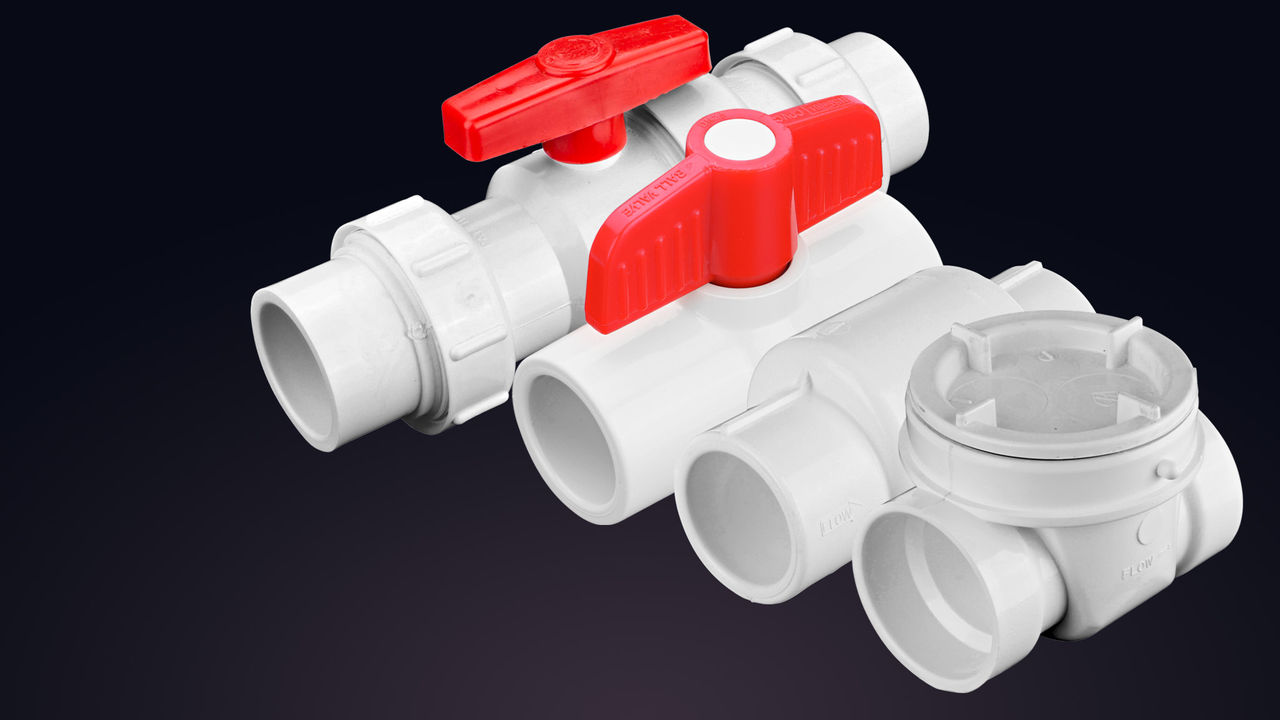

NDS StormChamber systems do not require an external manifold system. We rely on our internal side portal connections using a 10 in. PVC pipe to connect the rows. This allows water to travel laterally between chamber rows. It also works as an emergency spillway for long lasting high intensity storm events. Eliminating the manifold leads to a smaller footprint, less excavation, stone, and material cost which allows NDS StormChamber systems to have a lower installed cost than competing systems.

A manifold system may be used if specified by the engineer; a manhole with weir would also be required to direct the inflow to the SedimenTrap row.

Yes. NDS StormChamber systems have successfully tested and are in compliance with ASTM F2787 standard for plastic storm water chambers.

The spacing between the rows of chambers should only be measured from the centerline of one chamber to the adjacent chamber instead of measuring the distance between rows.

|

Chamber Model |

SC-18 |

SC-34 & SC-34W |

SC-44 |

|

Chamber Width |

38 in. (965mm) |

60 in. (1524mm) |

77 in. (1955mm) |

|

Separation |

6 in. (150mm) |

9 in. (225mm) |

9 in. (225mm) |

|

Centerline to Centerline |

44 in. (1117mm) |

69 in. (1752mm) |

86 in. (2184mm) |

Only ¾ in. to 2 in. crushed washed angular stone or concrete may be used. Under no circumstances should round stone be used.

Either stone or soil can be used as fill above an NDS StormChamber system.

Refer to the following table for the diameter sizes each chamber can accept.

|

|

SC-18 |

SC-34 |

SC-44 |

|

End wall |

15 in. |

30 in. |

36 in. |

|

Top portal |

10 in. |

10 in. |

10 in. |

|

Side portal |

8 in. |

10 in. |

10 in. |

No. The NDS StormChamber product line has been available since 1998 and has been trusted on hundreds of projects.

Tracked equipment must not exceed 1100 lbs (500kg) per square foot always maintaining a minimum of 6 in. stone below.

NDS StormChamber products can be purchased at any NDS distributor. Most all distributors are set up to sell NDS products. Please contact NDS if you have any questions or need help finding an authorized distributor near you.