Grade Poses Challenge that Trench Drain Design Meets

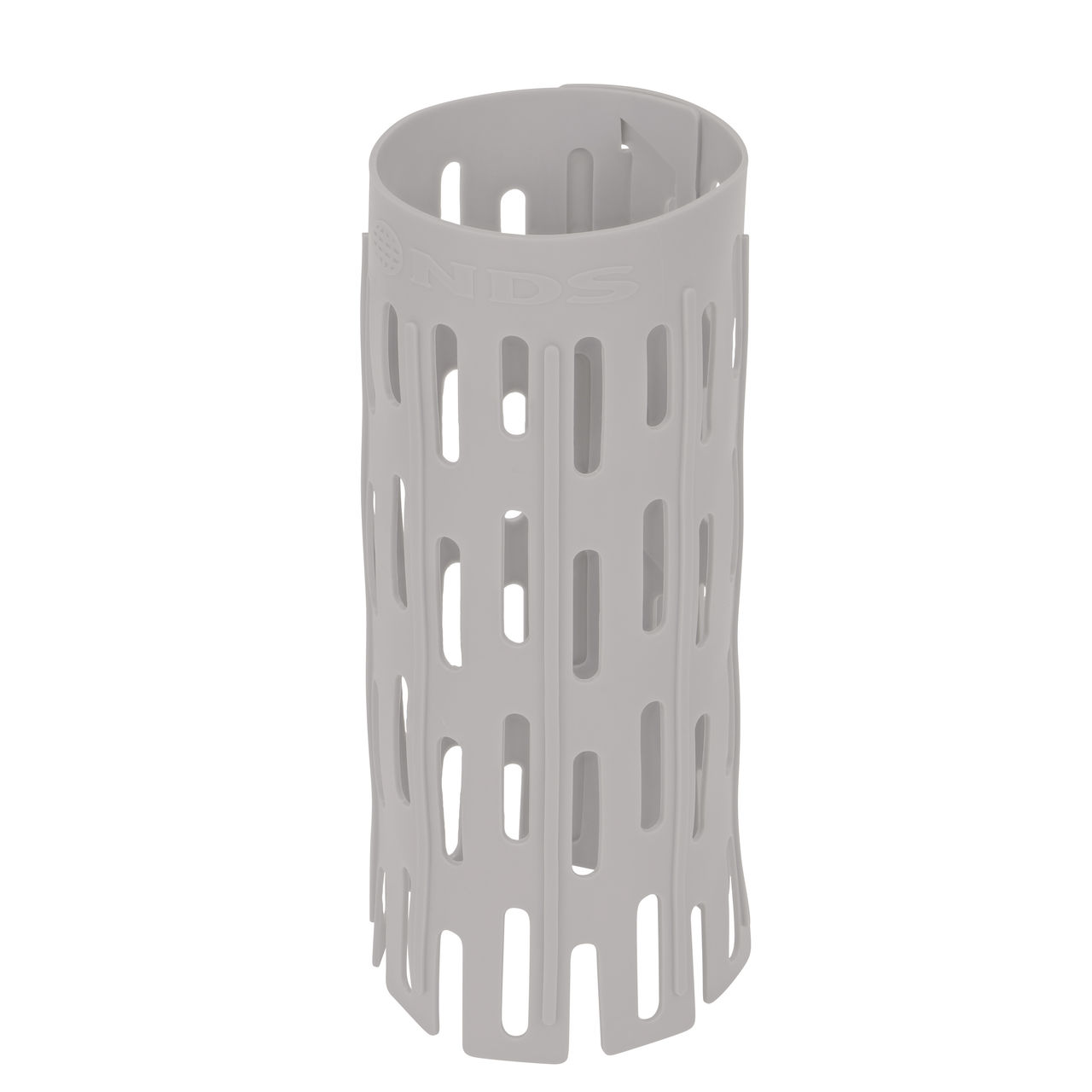

The construction crew required product relatively fast so they worked with their distributor, who knew that NDS could supply what they needed quickly with local NJ-based inventory. Once NDS received an overview of the project, the team recommended BG-FILCOTEN trench drains and provided a complete design and roadmap for the construction team.

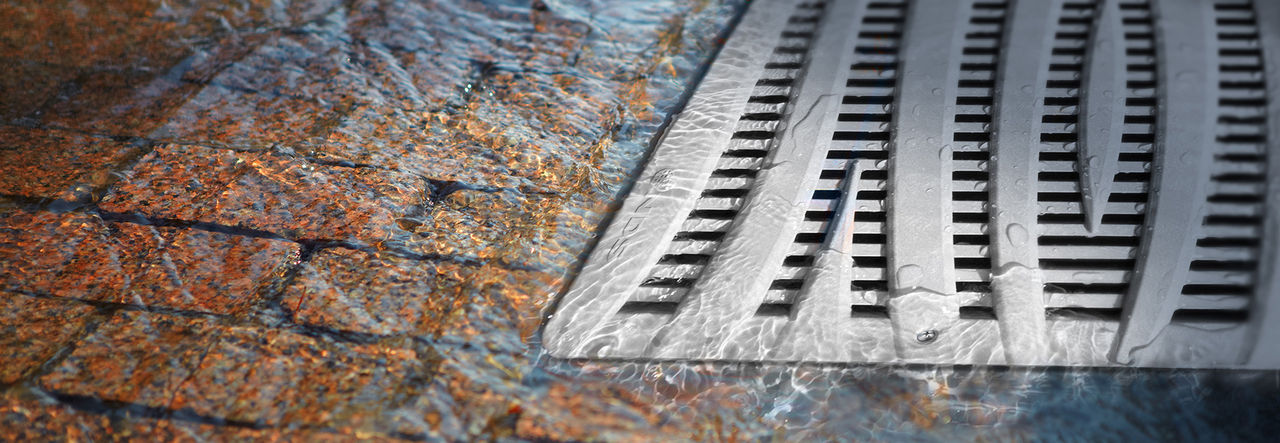

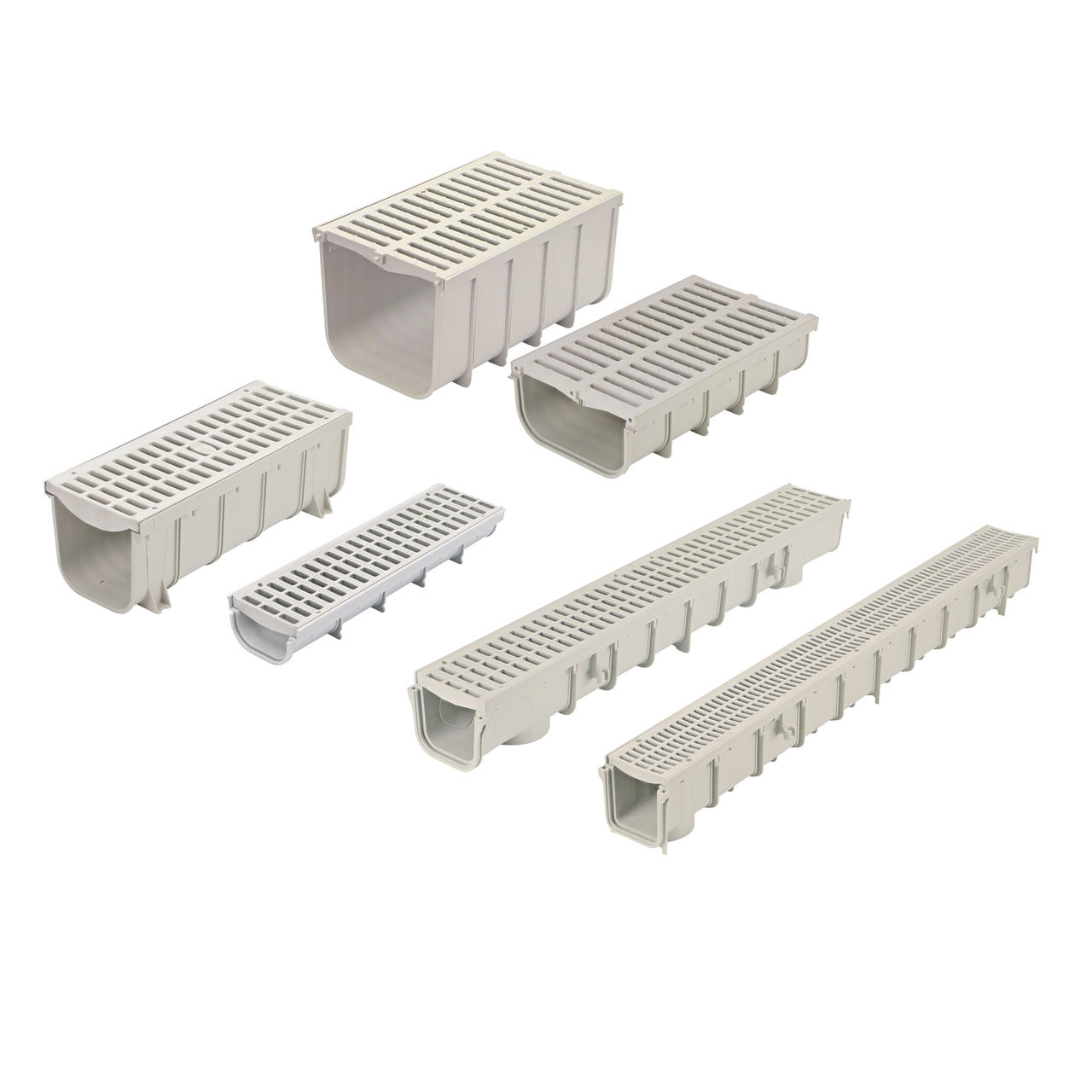

BG-FILCOTEN drains are 100% recyclable with 0% harmful substances – there are no heavy-metal residues that could leach into the ground and they enable a wider intake of sheet flow runoff. The drains are also capable of handling extremely heavy loads – meeting up to load class E, perfect for a high traffic area comprising mostly commercial vehicles and tractor trailers. Perhaps the most critical element of the product being installed at the fueling station is that it’s manufactured without resins, making it A1 rated, non-combustible and non-flammable.

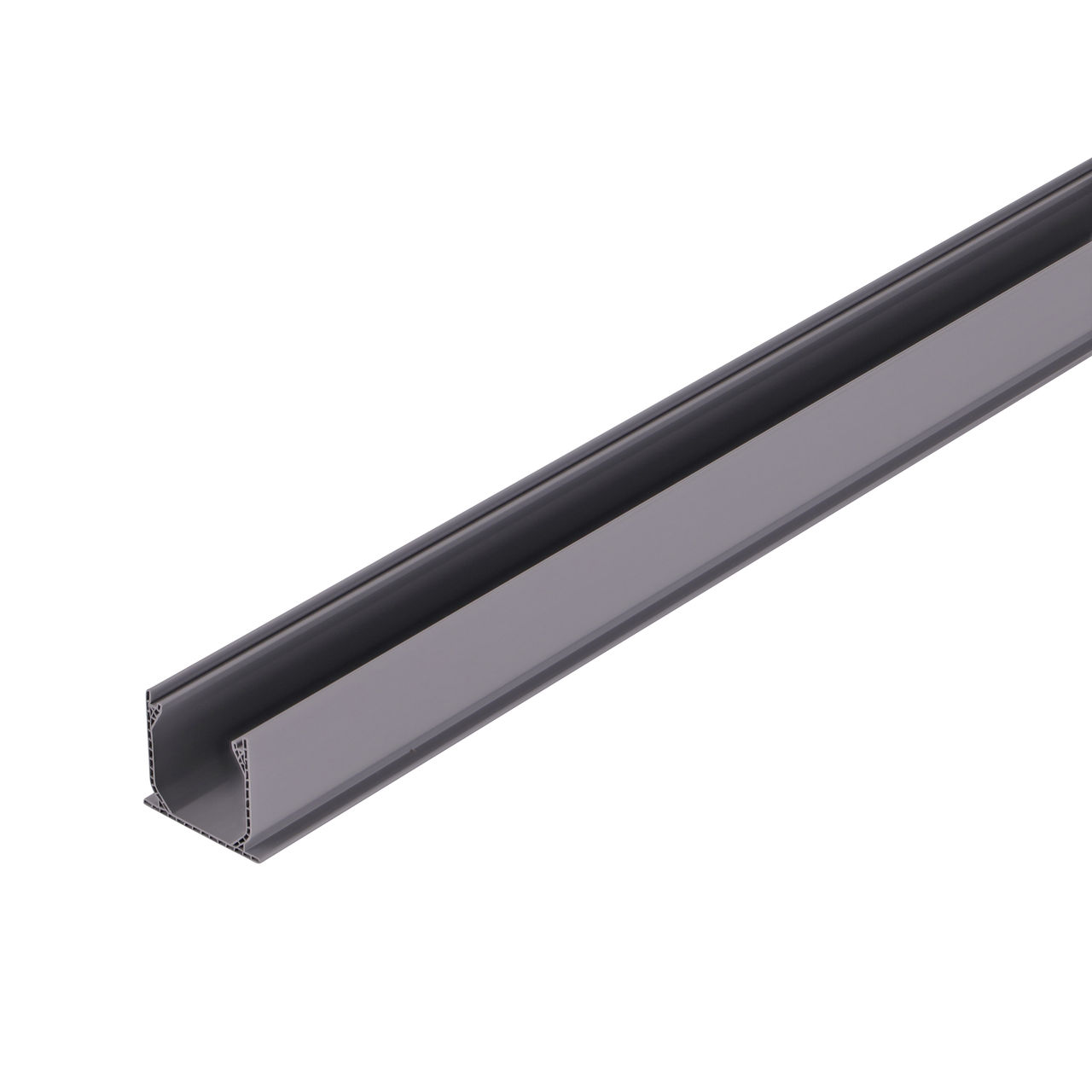

In addition, the product is offered in multiple sizes and comes in both pre-sloped and neutral configurations, which made it easier to install with the site’s grading.

NDS Drawings Prove Useful Prior to Install

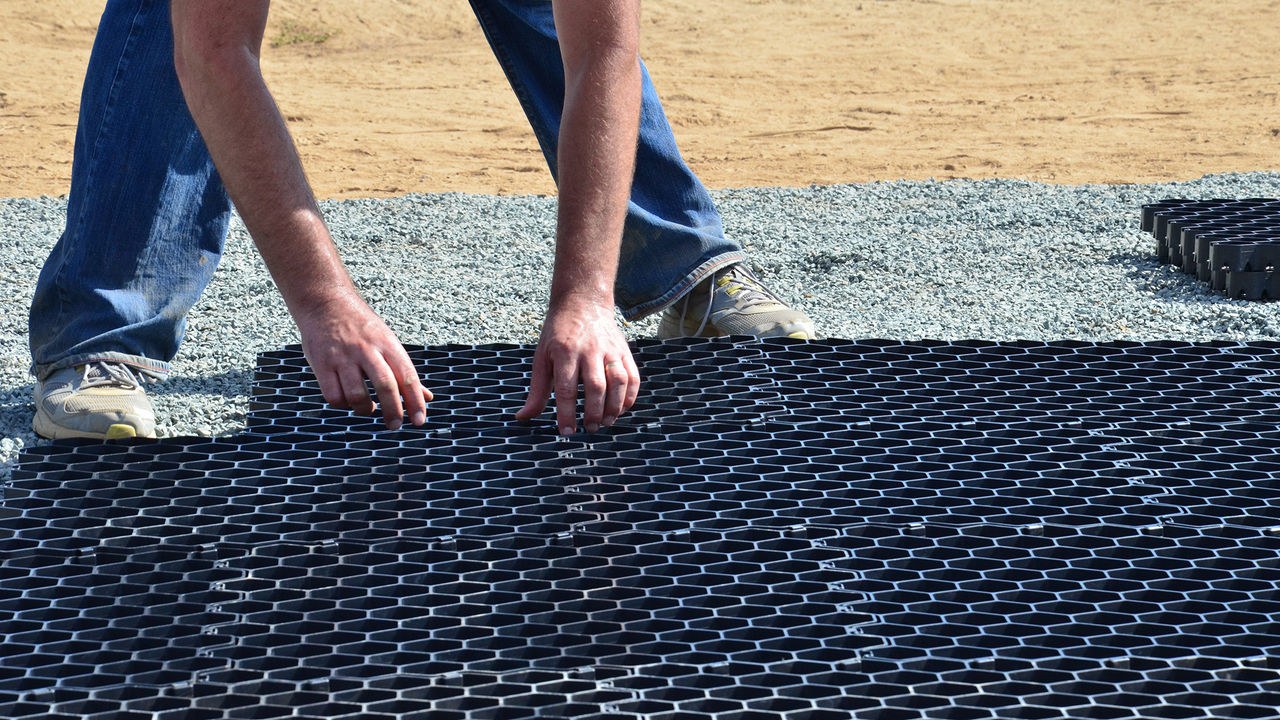

Product was ordered and delivered immediately thanks to a local DC, and the NDS Design Worx® team helped keep the project on track by providing the construction team with a drawing layout. Given the construction company had no prior experience installing BG-FILCOTEN, they were impressed as the NDS layout included scaled views of the building, location and flow of the drains, technical specifications, a materials list, and installation details.

With extensive experience in the petrochemical market, the construction company liked the way the product installed and appreciated the technical proficiency of the Design Worx team. It made the installation process go more smoothly.